Shell & tube heat exchangers offer large surface area in combination with efficient heat transfer and compactness. These are widely used in industries for various duties like cooling, heating, condensation, evaporation etc. GOEL are the pioneers in the field of glass shell and tube heat exchangers in India and their product has a wide market acceptability.

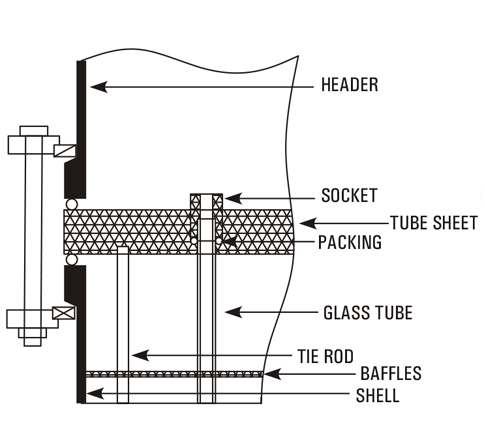

The glass tubes are sealed individually into PTFE tube sheet with special PTFE sockets and packing. This unique ferrule type sealing arrangement permits easy replacement and cleaning of tubes. Baffles on shell side ensure improved heat transfer by increased turbulance. Further details of construction can be seen in the diagram.

Three basic versions * are available :

| MATERIAL OF CONSTRUCTION OF SHELL & TUBE HEAT EXCHANGER | ||||

|---|---|---|---|---|

| Model | Shell | Tube | Header | Duty |

| RGG | Glass | Glass | Glass | For heat transfer between two aggressive media. |

| RGM | Glass | Glass | Steel/FRP | For heat transfer between aggressive media in shell & non-aggressive media in tubes. |

| RMG | Steel/FRP | Glass | Glass | For heat transfer between aggressive media in tubes & non-aggressive media in shell |

| Cat.Ref. RGG/RMG |

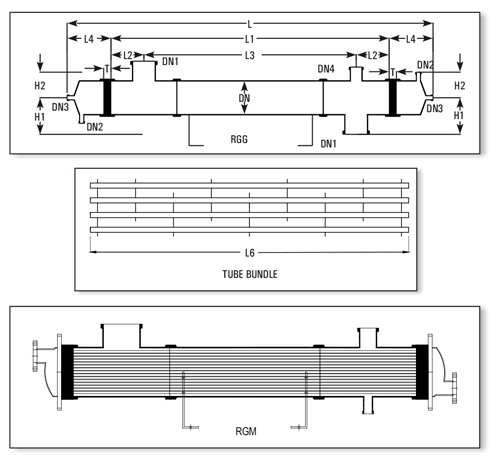

6/3 | 6/4 | 6/5 | 6/6 | 9/6 | 9/8 | 9/10 | 9/12 | 12/12 | 12/16 | 12/21 | 12/25 | 16/21 | 16/25 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Area (m2) | 3 | 4 | 5 | 6 | 6 | 8 | 10 | 12 | 12 | 16 | 21 | 25 | 21 | 25 |

| DN | 150 | 225 | 300 | 400 | ||||||||||

| DN1 | 80 | 100 | 150 | 225 | ||||||||||

| DN2 | 50 | 80 | 80 | 100 | ||||||||||

| DN3 | 25 | 40 | 40 | 50 | ||||||||||

| DN4 | 50 | 50 | 50 | 80 | ||||||||||

| H1 | 175 | 250 | 300 | 450 | ||||||||||

| H2 | 150 | 200 | 250 | 300 | ||||||||||

| L | 2500 | 3100 | 3700 | 4300 | 2620 | 3220 | 3820 | 4520 | 2550 | 3150 | 3950 | 4550 | 3100 | 3500 |

| L1 | 1900 | 2500 | 3100 | 3700 | 1900 | 2500 | 3100 | 3800 | 1800 | 2400 | 3200 | 3800 | 2000 | 2400 |

| L2 | 150 | 150 | 150 | 150 | 225 | 225 | 225 | 225 | 225 | 225 | 225 | 225 | 400 | 400 |

| L3 | 1600 | 2200 | 2800 | 3400 | 1450 | 2050 | 2650 | 3350 | 1350 | 1950 | 2750 | 3350 | 1200 | 1600 |

| L4 | 250 | 250 | 250 | 250 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 550 | 550 |

| L5 | 125 | 125 | 125 | 125 | 175 | 175 | 175 | 175 | 175 | 175 | 175 | 175 | 225 | 225 |

| L6 | 1980 | 2580 | 3180 | 3780 | 2000 | 2600 | 3200 | 3900 | 1930 | 2530 | 3330 | 3930 | 2185 | 2585 |

| T | 50 | 60 | 75 | 100 | ||||||||||

| No. of Tubes | 37 | 73 | 151 | 241 | ||||||||||

| No. of Baffles | 11 | 15 | 19 | 23 | 7 | 9 | 13 | 17 | 5 | 7 | 9 | 11 | 5 | 7 |

Permissible temperature range for both shell & tube sides – 40° C to 150° C.

Maximum permissible temperature difference between shell & tube sides 120° C.

All sizes & models are suitable for full vacuum on both side. Maximum limiting pressures are tabulated here below :

| MAXIMUM PERMISSIBLE PRESSURE RANGE, KG/CM2(G) | ||||

|---|---|---|---|---|

| Model | Side | 150DN | 225DN | 300DN |

| RGG | Shell-Tube Tube-Glass Dome-Glass |

2.0 2.0 |

1.0 1.0 |

1.0 1.0 |

| RGM | Shell-Tube Tube-Glass Dome-Glass |

2.0 3.5 |

1.0 3.5 |

1.0 3.5 |

| RMG | Shell-Tube Tube-Glass Dome-Glass |

3.5 2.0 |

3.5 1.0 |

3.5 1.0 |

The above ranges of applications are admissible limiting values. For each specific case GOEL recommends the admissible operating data based on the relations between pressure and temperature, size and mode

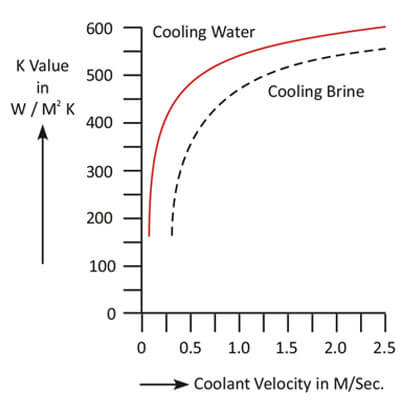

The particular advantage of shell & tube heat exchanger is high heat transfer performance. The relation between heat transfer and velocity of flow can be easily seen in the diagram. On receipt of the operating data from client the most favourable shell and tube heat exchanger is selected. This accurate design combined with most reliable quality assurance ensures economy and operational reliability for the user. For approximate sizing some typical heat transfer coefficients are given here below :

| U-VALUES | |||

|---|---|---|---|

| Media | Use | kcal/m2hrk | W/m2k300 |

| Steam water | condensation | 350-550 | 410-640 |

| Water – water | cooling | 250-350 | 290-410 |

| Water – air | cooling | 30-60 | 35-70 |

The overall heat transfer coefficient in a shell and tube heat exchanger is approximately three times higher than in a coil type heat exchanger, leading to more efficient heat transfer. The pressure drop in a shell and tube heat exchanger is minimal compared to the significant pressure drop experienced in the coil side of a coil type heat exchanger. For applications requiring higher heat transfer areas, the shell and tube heat exchanger is the preferred choice due to its superior performance.

Glass shell and tube heat exchangers are suitable for a wide range of duties such as cooling, heating, condensation, and evaporation in various industries. If you require efficient heat transfer, corrosion resistance, and compactness, a glass shell and tube heat exchanger may be the ideal choice for your application.

While the initial cost of a glass shell and tube heat exchanger may be higher than traditional metal-based heat exchangers, it offers long-term cost savings due to its durability, universal corrosion resistance, and minimal maintenance requirements. Additionally, the efficiency and performance benefits of glass shell and tube heat exchangers often justify the initial investment over time.