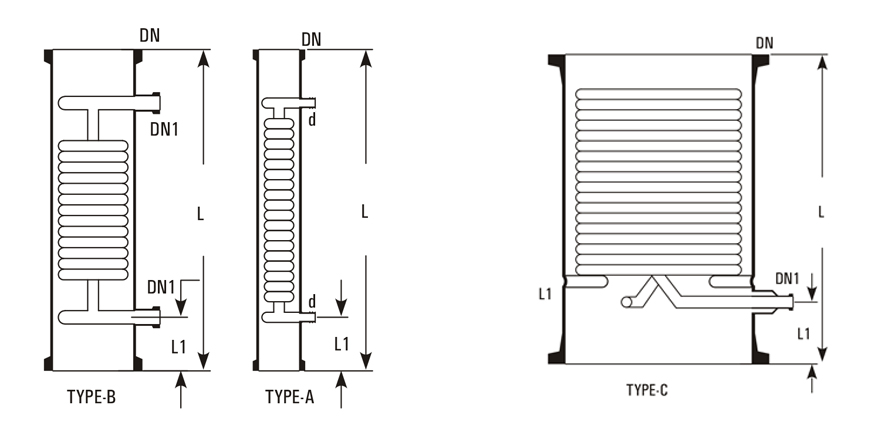

Coil Condensers are used for condensation of vapours and cooling of liquids. Condensers are made by fusing number of parallel coils in a glass shell. Coils are made in different diameters using tubes of different bores.

| Cat.Ref. | DN | d/DN1 | L | L1 | Type | Actual H.T.A. m2 |

Cross Area Cm2 |

Free Coolant Rate kg/hr. |

Max. Jacket Cap. Litre |

|---|---|---|---|---|---|---|---|---|---|

| HE3/3.5* | 80 | 16 | 600 | 75 | A | 0.35 | 5 | 1300 | 2 |

| HE4/5* | 100 | 19 | 600 | 75 | A | 0.50 | 30 | 2400 | 4 |

| HE4/6* | 100 | 19 | 750 | 100 | A | 0.60 | 30 | 2400 | 6 |

| HE6/10 | 150 | 25 | 600 | 100 | B | 1.00 | 52 | 2600 | 9 |

| HE6/15* | 150 | 25 | 850 | 100 | B | 1.50 | 52 | 2600 | 11 |

| HE9/25* | 225 | 25 | 800 | 110 | B | 2.50 | 125 | 3300 | 18 |

| HE12/25 | 300 | 25 | 600 | 125 | B | 2.50 | 175 | 5700 | 25 |

| HE12/40* | 300 | 25 | 900 | 125 | B | 4.00 | 175 | 5700 | 35 |

| HE16/40 | 400 | 25 | 600 | 125 | B | 4.00 | 450 | 6200 | 60 |

| HE16/50 | 400 | 25 | 700 | 125 | B | 5.00 | 450 | 6200 | 70 |

| HE18/60 | 450 | 40 | 750 | 150 | C | 6.00 | 820 | 4800 | 100 |

| HE18/80 | 450 | 40 | 900 | 150 | C | 8.00 | 820 | 6200 | 110 |

| HE24/120 | 600 | 50 | 1250 | 300 | C | 12.00 | 1520 | 6200 | 265 |

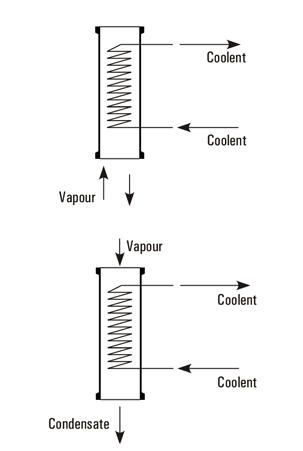

This method is simple to install over a reactor. However this results in condensate returning substantially at its condensing temperature. In this method care must be taken that condensate is not excessive that it can lead to “logging” the coils and create back pressure in the system. Generally a reflux divider is used below the condenser to take out the distillate.

This method produce a cool condensate using the entire coolinlg surface area. This method should be used where the condensate can lead to “logging” of coils.